Adapt your warehouse to changing demands with expert reconfiguration services that minimize disruption and maximize operational efficiency.

In today’s fast-paced supply chain environment, change is the only constant. Product lines shift. Customer expectations evolve. Order volumes spike. And what once felt like the perfect warehouse setup may now be holding your operations back.

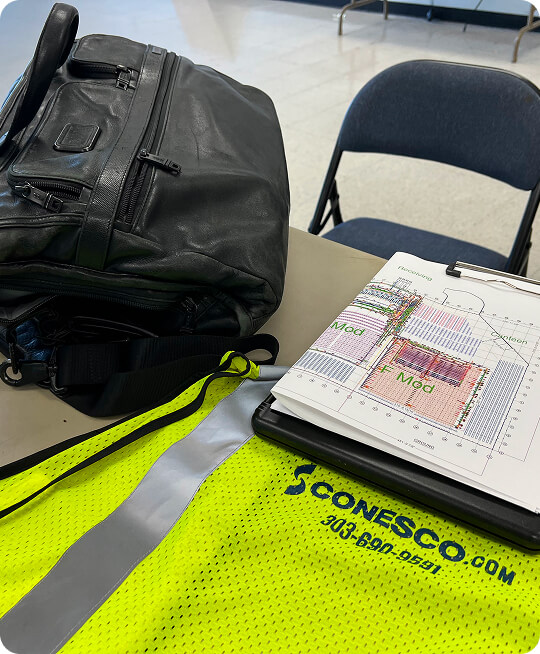

That’s where Conesco’s Facility Reconfiguration services come in.

With over 35 years in the material handling industry and a nationwide team of warehouse professionals, Conesco specializes in redesigning and reconfiguring warehouse layouts to match your changing business needs. Whether you’re expanding, consolidating, pivoting product strategy, or simply trying to get more out of your space, we help you adapt your facility with minimal downtime and maximum ROI.

We don’t believe in “one-size-fits-all.” Every warehouse we reconfigure starts with a deep understanding of how your business operates—from product flow and inventory type to labor deployment and safety priorities. Our team then designs and implements a custom plan that aligns with your operational goals.

Reconfigure selective, push-back, drive-in, cantilever, or flow systems to increase storage density or improve pick efficiency.

Adjust spacing for better forklift travel, safer pedestrian movement, or new equipment requirements.

Shift or resize mezzanines to meet changing workflow needs or vertical space usage.

Move or modify conveyors for new order routing or shipping schedules.

Support transitions to FIFO, LIFO, or SKU-based storage strategies.

Ensure your new layout maintains fire code, egress, and seismic compliance.

Relocate guards, signage, column protectors, and barriers as your layout changes.

If any of that sounds familiar, your warehouse may be due for a reconfiguration. We’re here to help you get more from what you already have.

We make it easy to modernize your warehouse without starting from scratch. Our reconfiguration process is designed for minimal disruption and maximum results.

We visit your site (or review detailed floor plans) to understand your current layout, equipment, and constraints. We listen to your pain points and performance targets.

We evaluate product movement, storage systems, labor use, and material flow to find inefficiencies and bottlenecks.

Using CAD and engineering tools, we develop new layout options that better support your storage, retrieval, and shipping requirements. This may involve rearranging racks, adding equipment, or even reducing square footage for efficiency.

If your reconfiguration includes structural changes or high-pile storage, we provide stamped drawings and assist with local permitting requirements.

Need to keep operations running while you reconfigure? No problem. Our team can work in phases, off-shifts, or weekends to minimize disruption. We’ve supported reconfigurations in active distribution centers, cold storage facilities, and high-volume e-commerce hubs.

Whether you’re operating on tight seasonal timelines or multi-year growth plans, we build the schedule around you.

Your warehouse needs to perform today, but it also needs to grow with you tomorrow. Every Conesco reconfiguration is designed with future flexibility in mind. We’ll help you build in options for:

Wherever you are in your warehouse lifecycle, Conesco is your go-to partner for smart, strategic change.

Stay ahead of problems and streamline maintenance schedules.

Ensure compliance with OSHA, NFPA, and local fire codes.

Prep for inspections, insurance visits, or corporate audits.

Identify hazards and document risk mitigation efforts.

Partner with Conesco to verify subcontractor safety before handoff.

Our approach goes beyond inspection. We bring decades of experience, deep code knowledge, and full-service capabilities to keep your warehouse safe and compliant at every level.

We’ve redesigned hundreds of warehouses—from 10,000 to 1,000,000 square feet.

From layout and permits to equipment and labor, we handle it all.

Crews and planners available across the U.S.

Every project is executed with OSHA-compliant protocols.

We bring practical insight, not just theoretical ideas.

Over 400+ Years of Collective Industry Experience

With team members and locations across the nation, Conesco is here to handle all of your pallet racking, MHE, decommissioning, and labor needs. Contact us today to start on your next project.

Conesco provides expert solutions for all your material handling needs. Our team is ready to assist you in finding the right equipment for your project. Fill out the form to get started!