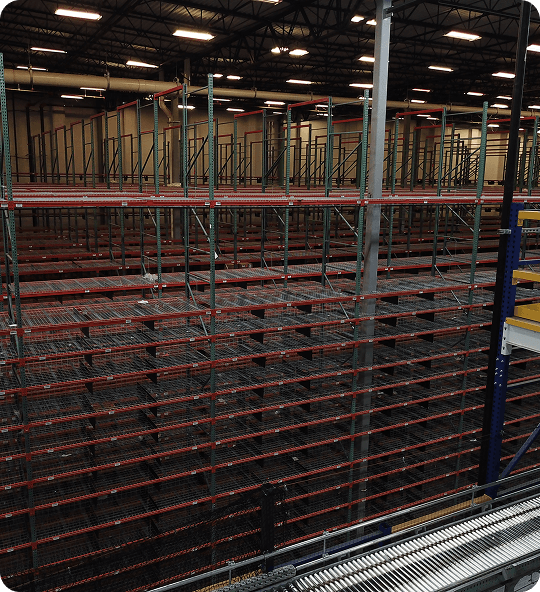

Are you looking to purchase warehouse products like pallet racking (uprights, beams, wiredecks/pallet supports, row spacers, column guards, end aisle guards, + more), pick modules, mezzanines, cantilever rack, shelving, or specialty material handling equipment?

Uprights, beams, wire decks, pallet supports, row spacers

Best Flex, Accumulation, Photo Eye, Roller, Belt.. Many different use cases!

Find a mezzanine the fits your load capacity, size, and design features to meet your operational needs

Vertical columns (‘towers’), horizontal bases, arms, bracing, and hardware

Mezzanines/ platforms, conveyor, racking/ shelving, stairs, safety equipment (ie guardrails)

Forklifts, reach trucks, AS/RS, pallet jacks, balers, scales, wrapping machines, truck loaders, dock ramps, +more

Double Water Fall, Flared, Reverse Water Fall, Drop-in, Flush

Industrial Steel Shelving, Boltless, Steel, +more

Mezzanines/ platforms, conveyor, racking/ shelving, stairs, safety equipment (ie guardrails)

Double Water Fall, Flared, Reverse Water Fall, Drop-in, Flush

Collaboration that helps you pinpoint your needs and plan every step of the way. Get the best solutions while saving time and money.

Customers spanning different industries across the world.

Third Party Logistic companies leverage Conesco to offer customized material handling solutions to meet the unique needs of the diverse client products while helping to streamline supply chain operations.

Request A Quote

Ecommerce fulfillment centers rely on Conesco to fulfill their material handling system needs...to maximize storage capacity while efficiently processing and shipping orders to customers.

Request A Quote

Third Party Logistic companies leverage Conesco to offer customized material handling solutions to meet the unique needs of the diverse client products while helping to streamline supply chain operations.

Request A Quote

Third Party Logistic companies leverage Conesco to offer customized material handling solutions to meet the unique needs of the diverse client products while helping to streamline supply chain operations.

Request A Quote

Third Party Logistic companies leverage Conesco to offer customized material handling solutions to meet the unique needs of the diverse client products while helping to streamline supply chain operations.

Request A Quote

Third Party Logistic companies leverage Conesco to offer customized material handling solutions to meet the unique needs of the diverse client products while helping to streamline supply chain operations.

Request A Quote

Have confidence in your project, timelines, budget, and operation.

Pallet Racking, Pick Modules, Conveyance, Mezzanines, Specialty Equipment, and More.

Uprights, beams, wire decks, pallet supports, row spacers

Best Flex, Accumulation, Photo Eye, Roller, Belt.. Many different use cases!

Find a mezzanine the fits your load capacity, size, and design features to meet your operational needs

Vertical columns (‘towers’), horizontal bases, arms, bracing, and hardware

Mezzanines/ platforms, conveyor, racking/ shelving, stairs, safety equipment (ie guardrails)

Forklifts, reach trucks, AS/RS, pallet jacks, balers, scales, wrapping machines, truck loaders, dock ramps, +more

Double Water Fall, Flared, Reverse Water Fall, Drop-in, Flush

Industrial Steel Shelving, Boltless, Steel, +more

Over 400+ Years of Collective Industry Experience

With team members and locations across the nation, Conesco is here to handle all of your pallet racking, MHE, decommissioning, and labor needs. Contact us today to start on your next project.

“In a project that had many moving parts and a very tight timeline for us to be out of the facility, Conesco’s focus and drive to deliver was impressive. We are glad we we chose to work with them and consider them our go to resource in the material handling world.”

Global eCommerce Company

“I’ve worked with Conesco over 20 years at three different companies. I continue to work with them because they deliver on what they say, they hit timelines, and when problems arise, they address it head on with multiple solutions.”

Warehousing, 3PL, & National Retail Companies

“In a project that had many moving parts and a very tight timeline for us to be out of the facility, Conesco’s focus and drive to deliver was impressive. We are glad we we chose to work with them and consider them our go to resource in the material handling world.”

Global eCommerce Company

“I’ve worked with Conesco over 20 years at three different companies. I continue to work with them because they deliver on what they say, they hit timelines, and when problems arise, they address it head on with multiple solutions.”

Warehousing, 3PL, & National Retail Companies

Material handling equipment encompasses the various machines, tools, vehicles, and solutions used for effective loading, unloading, storage, movement, and control of goods and materials within a warehouse, manufacturing plant, or distribution facility.

Material handling equipment provides solutions for:

Material handler equipment includes a broad range of items, including industrial material handling equipment and automated material handling equipment. This specialized equipment is generally in one of four categories:

New equipment is preferable, providing modern solutions and warranty coverage.

However, it is not always the best solution. You will want to examine whether your needs can be met just as well by buying used material handling equipment. While it may not be state-of-the-art, it may work just fine, and you can save a significant amount of money.

For example, well-maintained pallet racks can last for decades. Used pallet racks might save you as much as 30% to 50% over buying new, which is beneficial when budgets are tight or you want to spend money elsewhere.

Avoid long lead times on new or custom-ordered equipment and quickly meet operational demands or replace broken machinery to minimize downtime.

Reduce waste and raw material consumption while benefiting from durable, warehouse-tested equipment with a track record of reliability.

Stretch your budget by acquiring used equipment for seasonal peaks or short-term needs, avoiding unnecessary long-term expenditures.

The right used equipment offers cost savings without sacrificing quality, but working with a trusted supplier is essential to ensure true value.

As warehousing and fulfillment challenges intensify, purchasing equipment based solely on cost is shortsighted. You need an experienced partner who takes a consultative approach to understand your operations and design optimized solutions.

Evaluating order processing steps, bottlenecks, redundancy, excess motion, and other optimization opportunities.

Accounting for fluctuating order volumes and capacity, including seasonal spikes.

Assessing available storage density and layout equipment for efficient material flow within existing square footage or racking.

Preventing equipment additions from introducing new operator hazards or chokepoints that limit throughput.

Reviewing current automation technologies to identify areas where added capabilities could boost efficiency.

You should also look for new and used material handling equipment suppliers with extensive experience in warehouse design. They can help you configure equipment to work within an optimized facility layout and offer suggestions to improve operations.

Not all sellers and resellers are highly knowledgeable about new technologies or products. They may know their product line but not others. Look for a supplier that stays current and knows the material handling industry as a whole.

There have been significant advances in material handling in the past few years, especially in the domain of automated material handling equipment. You want a partner who is on top of evolving technology and has experience with hardware and software controls.

While there are standards in the industry, every facility has its own flow and way of doing business. Depending on the legacy equipment you have and how you plan to use new equipment, make sure your partner is capable of creating customized solutions for you. Even with the same equipment, it is often the nuances of where and how it is placed that ensure an optimized workflow.

Whether you are buying or selling, working with an ethical supplier is crucial. When you are buying new equipment, you typically get warranty coverage. However, buying used material handler equipment is a different story. If you buy from an unknown seller—or someone who is not upfront about any defects—you could be setting yourself up for costly problems or safety issues.

When sourcing used material handling equipment, hidden issues and unfair pricing can lead to costly headaches. Even minor dents can cause failures over time, and some sellers may conceal wear to secure a sale, leaving buyers with performance issues.

A reliable supplier transparently discloses equipment conditions, from specifications to cosmetic flaws, helping you make informed decisions. Ethical suppliers offer fair market pricing upfront, preventing inflated costs and unexpected expenses. They also identify potential compatibility issues, as not all components are interchangeable.

Beyond avoiding risks, the right supplier acts as a partner, analyzing your inventory systems and workflows to provide tailored solutions that enhance efficiency and maximize value.

The same strategy applies when selling equipment, whether closing a business, liquidating assets, upgrading, or offloading excess material handlers. Finding a trustworthy broker is key.

To maximize value, research fair market prices using industry indexes, auction data, and valuation resources, keeping in mind that older equipment may depreciate due to evolving efficiency and safety standards. Market conditions, such as large liquidations, can also impact resale prices.

Accurately catalog your equipment, including manufacturers, product IDs, serial numbers, images, and maintenance records. Transparency about cosmetic flaws and performance ensures a smoother sales process and buyer confidence.

Partnering with an experienced reseller or liquidator like Conesco streamlines sales, leveraging a vast buyer network to secure optimal prices.

Your next step is to contact the material handler equipment experts at Conesco Storage Systems.

As one of the industry’s highest-volume equipment dealers, Conesco provides affordable options for new and used equipment. We thoroughly evaluate used equipment to confirm its condition and accurately detail its remaining useful life projections before reselling.

As one of the country’s largest warehouse liquidators, we have access to a global network of buyers to get you top dollar for your equipment.

Beyond fair prices for trustworthy equipment, our expertise smooths out transition hurdles. Conesco’s experienced handling crews can safely and properly dismantle, crate, and transport assets to avoid damage en route to new facilities.

The four main purposes of material handling systems include:

Movement: Transporting materials, components, and products between different locations, such as between storage areas, workstations, or shipping and receiving areas.

Positioning: Placing the materials, parts, or products where needed.

Storage: Storing and protecting products in warehouses, distribution centers, or fulfillment centers until needed.

Control: Tracking material locations and information, such as quantities and manufacturing status. Controlling work-in-process and inventory levels, often using automated material handling equipment.

Conesco provides expert solutions for all your material handling needs. Our team is ready to assist you in finding the right equipment for your project. Fill out the form to get started!