At Conesco Storage Systems, we believe experience is everything. When it comes to material handling, there’s no substitute for working with people who truly know the equipment, the process, and the pressure points of warehouse operations.

That’s why we’ve built a nationwide team of seasoned material handling specialists who bring decades of hands-on knowledge to every project. From racking and conveyors to facility decommissions and complex reconfigurations, our experts are here to guide you through it all.

With over 400+ combined years of industry experience across our team, Conesco’s experts don’t just understand the equipment—we understand how it fits into the bigger picture of your operations. We’re problem-solvers, planners, engineers, project managers, and logistics pros who work together to deliver seamless, scalable warehouse solutions.

Need help with a major install or teardown? Our labor crews are trained in OSHA-compliant practices and can be deployed nationwide. We get the job done right, whether it’s racking, mezzanines, conveyors, or safety accessories.

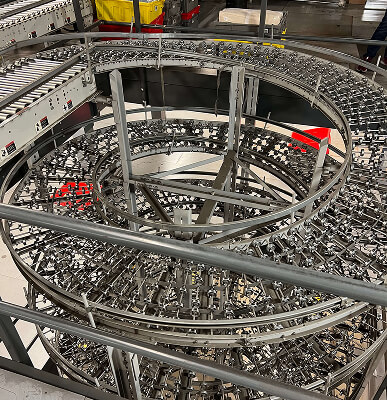

From powered conveyor belts to gravity-fed systems, our conveyor experts help design, install, and maintain systems that support efficient product flow across your facility.

Looking to expand your usable space without relocating? We design and install mezzanine systems that maximize vertical real estate and increase storage capacity.

Selective, push-back, drive-in, pallet flow, cantilever—we’ve worked with every racking system out there. Our team helps select and configure the right rack layout to support your product weight, access needs, and floor space.

Moving out? Shutting down? Repurposing a facility? We specialize in full-service decommissions—disassembly, asset recovery, buyback, freight, and clean-out.

Need lockers, carousels, pick modules, stack racks, or lifts? We know how to source, install, and integrate these specialized pieces into your broader warehouse system.

Our permitting experts work closely with licensed engineers to provide stamped drawings and handle jurisdictional compliance, so you can stay focused on the bigger picture.

Uses nested carts on inclined rails to push pallets back as new ones are loaded, optimizing space and accessibility.

Over 400+ Years of Collective Industry Experience

With team members and locations across the nation, Conesco is here to handle all of your pallet racking, MHE, decommissioning, and labor needs. Contact us today to start on your next project.

CEO

National Account Manager

National Account Manager

National Account Manager

National Account Manager

National Account Manager

National Account Manager

Off-Site Project Manager

Conesco’s team isn’t made up of sales people in suits. Our experts have worked on the warehouse floor, run crews, managed logistics, and installed thousands of racking systems. We’ve seen what works and what doesn’t—and we’re not afraid to tell you when there’s a better way.

We’re here to consult, not just sell. Whether you’re opening a new distribution center, relocating your facility, or trying to solve a recurring traffic flow issue, we approach each challenge with deep industry insight and a mindset for optimization.

Our customers work with us because we deliver outcomes—not just products. Here’s what you can expect from our team of material handling experts:

Focusing on our customer’s needs and bringing them maximum value, since 1986.

We know how to make the most of every square foot in your warehouse, reducing dead space and increasing storage density.

Our experience means we can plan better, anticipate issues, and move projects forward with minimal downtime.

We prioritize safety and compliance, ensuring your system meets all regulatory requirements and internal safety standards.

Our solutions are built with the future in mind, giving you room to grow, adapt, and respond to changes in your operation.

We evaluate every aspect of your project to recommend cost-effective alternatives that don’t compromise quality or performance.

“In a project that had many moving parts and a very tight timeline for us to be out of the facility, Conesco’s focus and drive to deliver was impressive. We are glad we we chose to work with them and consider them our go to resource in the material handling world.”

Global eCommerce Company

“I’ve worked with Conesco over 20 years at three different companies. I continue to work with them because they deliver on what they say, they hit timelines, and when problems arise, they address it head on with multiple solutions.”

Warehousing, 3PL, & National Retail Companies

“In a project that had many moving parts and a very tight timeline for us to be out of the facility, Conesco’s focus and drive to deliver was impressive. We are glad we we chose to work with them and consider them our go to resource in the material handling world.”

Global eCommerce Company

“I’ve worked with Conesco over 20 years at three different companies. I continue to work with them because they deliver on what they say, they hit timelines, and when problems arise, they address it head on with multiple solutions.”

Warehousing, 3PL, & National Retail Companies

We start every relationship with a conversation. We want to understand what’s working in your current system, what’s not, and what you envision for the future. From there, we bring in the right experts to design a strategy that’s aligned with your goals, budget, and timeline.

Throughout the process, you’ll have a dedicated project manager who coordinates our internal team and keeps you informed every step of the way. You won’t be passed around between departments—you’ll have consistent support from professionals who know your project inside and out.

Your warehouse is too important to leave to chance. Conesco’s material handling experts are here to support you from start to finish, whether you’re building from the ground up or optimizing an existing facility.

We’ve spent decades learning the ins and outs of this industry so you don’t have to. Our role is to listen, advise, and deliver high-performance systems that keep your operation running smoothly.

Imagine a warehouse that runs like a well-oiled machine, where every square inch of space is optimized, inventory flows seamlessly, and productivity soars. The secret? Smart warehouse pallet racking systems. The right storage solution can transform your warehouse from a cluttered storage space to a streamlined powerhouse of efficiency.

In this guide, we’ll explain the types and methods of warehouse storage, the benefits of warehouse pallet racks, safety requirements, and how they integrate with other material handling equipment.

The most common and versatile type, offering direct access to every pallet, making it ideal for high-turnover inventory.

A standard racking system where each pallet is stored one deep per level, ensuring easy access and retrieval.

Enhances storage capacity by storing two pallets deep. Requires specialized forklifts for access.

Uses nested carts on inclined rails to push pallets back as new ones are loaded, optimizing space and accessibility.

High-density storage that allows forklifts to enter from either end. Commonly used for bulk storage.

A gravity-fed system designed for FIFO (First In, First Out) inventory management. Ideal for perishable goods.

Best for long, bulky, or irregularly shaped items like pipes, lumber, or steel bars.

Uses nested carts on inclined rails to push pallets back as new ones are loaded, optimizing space and accessibility.

Uses large racks to store palletized goods, making it ideal for bulky inventory.

Stacks multiple levels of racking to store high volumes of goods efficiently within a compact footprint.

Includes individual shelves to store smaller items, typically organized by category for easier retrieval.

Mounted on rails and can be moved to access specific sections, maximizing floor space.

Creates additional storage space by adding a raised platform within the warehouse to increase vertical storage capacity.

While there are different configurations for pallet racking, the basic components include upright frames, shelf beams, and support items.

Upright frames are made up of two metal columns that are braced internally. The columns have holes for horizontal beams to connect. You can get upright frames in a variety of heights, widths, and post sizes to handle different dimensions and weight loads.

Horizontal beams are the rails that attach to the frame and create the shelves. Pallet rack beams support loads and attach at the front and back of the upright frames. Typically, these come in either step beams or box beams, which can support wire decking or other additional support.

There are several supporting components to help manage weight loads and stability, including:

Third Party Logistic companies leverage Conesco to offer customized material handling solutions to meet the unique needs of the diverse client products while helping to streamline supply chain operations.

Pallet racking systems help protect your inventory by preventing unnecessary movement and reducing the risk of product damage. Unlike traditional floor stacking, racks provide structured storage that keeps goods securely in place.

Third Party Logistic companies leverage Conesco to offer customized material handling solutions to meet the unique needs of the diverse client products while helping to streamline supply chain operations.

Third Party Logistic companies leverage Conesco to offer customized material handling solutions to meet the unique needs of the diverse client products while helping to streamline supply chain operations.

Third Party Logistic companies leverage Conesco to offer customized material handling solutions to meet the unique needs of the diverse client products while helping to streamline supply chain operations.

Third Party Logistic companies leverage Conesco to offer customized material handling solutions to meet the unique needs of the diverse client products while helping to streamline supply chain operations.

Third Party Logistic companies leverage Conesco to offer customized material handling solutions to meet the unique needs of the diverse client products while helping to streamline supply chain operations.

The Occupational Safety and Health Administration (OSHA) has specific requirements for warehouse racking, covering installation, maintenance, and inspection standards.

OSHA recently launched a three-year program aimed at reducing and preventing workplace hazards in warehouses, fulfillment centers, and distribution centers. The main areas of focus include material handling and storage, walking and working surfaces, powered industrial vehicle operation, means of egress, and fire protection.

Conesco provides expert solutions for all your material handling needs. Our team is ready to assist you in finding the right equipment for your project. Fill out the form to get started!